В Pit Crushing and Conveying Wireless

2022-03-13T19:03:30+00:00

689+

производственное

оборудование

170+

страна

обслуживания

3200

численность

персонала

180+

государственный

патент

В Pit Crushing and Conveying Wireless

ResearchGate

Inpit crushing and conveying technology in openpit

2019年1月18日 InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is

Inpit crushing and conveying technology in openpit mining

Read this article InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is

Comparison of fixed and mobile inpit crushing and conveying

2020年9月1日 A new conceptual mining method called the nearface stockpile (NFS), which combines the inpit crushing and conveying IPCC system with a precrusher

Determination of semimobile inpit crushing and conveying

2021年2月12日 Inpit crushing and conveying (IPCC) is a material handling system with a feed system, crusher, conveyors and discharge systems as shown in Fig 1 It involves in

Mining Free FullText A Framework for OpenPit Mine

2021年3月8日 Abstract Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional

Gearing up for the next generation of mining inpit crush

Nov 16, 2021 Metso Outotec gears up for next generation of mining IPCC applications Inpit crush and convey (IPCC) has become a viable solution to the mining industry due to the

Features of using equipment for inpit crushing and

2023年1月2日 Abstract Purpose is to substantiate the use of an inpit crushing and conveying technology at the open pits with complex structure of the working zone, which

Energy consumption in openpit mining operations

2021年4月1日 In openpit mines, the traditional truckbased haulage system has consumed large amounts of energy in the haulage sector for many years The use of continuous in

How IPCC technology can support sustainability targets –

Inpit crushing and conveying: a flexible solution for sustainable mining Today, most mines depend on large mining trucks to haul material out of the mining pit to crushing and

Environmental Comparison of Different Transportation

2019年2月22日 Accordingly, introducing a substitutional transportation system that can reduce these effects is highly in demand InPit Crushing and Conveying (IPCC) systems in which the crusher station is located in the pit and crushed ore or waste transferred to its related destination through the conveyor belt, was introduced in 1956 in Germany

Inpit crushing and conveying technology in openpit

2019年1月18日 InPit Crushing and Conveying (IPCC) has gained popularity in the last two decades in the mining sector (Osanloo and Paricheh, 2020), in response to the decreasing ore quality and increasing needs

Different parts of IPCC system [3] Download

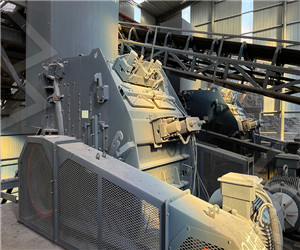

The IPCC system is a continuous ore processing system, which includes two main parts: crushing and conveying IPCC uses fully mobile, semimobile or fixed inpit crushers coupled with conveyors

Mining Free FullText Electrification Alternatives for Open Pit

2022年11月27日 Schroder, DL The use of inpit crushing and conveying methods to significantly reduce transportation costs by truck In Proceedings of the Coaltrans Asia Conference, Bali, Indonesia, 8–11 June 2003 [Google Scholar] Raaz, V; Mentges, U Inpit crushing and conveying with fully mobile crushing plants in regard to energy efficiency

Inpit Crush and Convey (IPCC) Metso

To better meet these challenges, Metso inpit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services The offering has been designed to ensure the highest productivity, energy efficiency, as well as maintainability

Review of Inpit Crusher Conveyor (IPCC) application

This paper therefore aims to review the recent history of IPCC applications in the mining industry and present the most recent systems installations There are a few successfully documented cases of fully mobile crusher conveyor applications To be economically feasible, semimobiel IPCC systems require productive reates on excess of 8000

Semimobile system [6] Download Scientific Diagram

The use of continuous inpit crushing and conveying (IPCC) systems is a viable option to significantly reduce energy consumption in this sector Considering the relationship between the energy

A heuristic approach for inpit crusher and conveyor

Inpit crushing and conveying (IPCC) and ore sorting are two developing technologies that, in addition to providing likely economic benefits, also have the potential to reduce the greenhouse gas

A Framework for OpenPit Mine Production Scheduling

Inpit crushing and conveying (IPCC) systems as alternatives to the truckandshovel system have attracted more attention today The IPCC system is composed of a series of

Rationale for mobile crushing plants design methodology

2020年11月11日 Several inpit crushingconveying systems have been installed at a few large surface mines around the world Data generated from such installations have revealed that, compared to conventional

Comparison of fixed and mobile inpit crushing and conveying

2020年9月1日 Inpit crushing and conveying (IPCC) systems (whether fixed, mobile, or semimobile) are an alternative to the traditional truck/shovel approach to materials handling, offering potential cost savings However, assessing the viability of one of these systems for an existing or planned openpit mine from an operational standpoint presents a great

A MinetoCrusher Model to Minimize Costs at a

2022年8月18日 The application of mobile inpit crushing and conveying in large, hard rock open pit mines In Proceedings of the Mining Magazine Congress, Toronto, ON, Canada, 8–9 October 2009 [Google Scholar]

The pit stop to cut your carbon footprint

2020年9月15日 The ‘change of tires’ we recommend is a switch from expit crushing and conveying (EPCC) to inpit crushing and conveying (IPCC) With EPCC the crushers and conveyors are located outside the pit or at the pit rim; with IPCC they are inside the pit The change of system to continuous open pit mining technology (IPCC) brings significant

looks for sustainable gains with thyssenkrupp mining

2021年8月25日 That can be with drystacked tailings, tailings management, IPCC (inpit crushing and conveying) systems, electrification of the pit, reducing emissions or dust, etc” Many of these solutions will enable companies to produce the same amount of product, or more, with the same input costs and energy draw, according to Schulz

ru/semi mobile crushing plant price в Бразилииmd at main

Contribute to businessgitv/ru development by creating an account on GitHub

(PDF) Determination of the optimal transition point

2021年9月1日 One of the most challenging aspects in semimobile inpit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truckbased haulage system

Review of the inpit crushing and conveying (IPCC

2023年11月11日 Inpit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost IPCC is the superior technology for

CHAPTER 105: InPit Crushing ResearchGate

Engineers InPit Crushing and Conveying Symposium in Salt Lake City, Utah (United States) in 1980 This combination of need, visibility, and credibility built

Mining Free FullText A Framework for OpenPit Mine

2021年3月8日 Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems However, the implementation of the IPCC system can reduce mining flexibility and introduce additional mining sequence requirements This paper investigates the long

Energy consumption in openpit mining operations

2021年4月1日 The use of continuous inpit crushing and conveying (IPCC) systems is a viable option to significantly reduce energy consumption in this sector Considering the relationship between the energy data and the amount of mineral extracted in the haulage sector of an openpit titanium mine and the production of openpit iron, copper and coal

(PDF) Inpit crusher location as a dynamic location problem

2017年6月1日 The cost efficiency and high reliability of semimobile or combined inpit crushingconveying (IPCC) and truck systems, compared to conventional truckshovel systems alone, make them more

Haulage systems for open pit mines Global Road

2022年11月9日 Inpit crushing and conveying IPCC systems consist of the application of a fully mobile, semimobile or fixedinpit primary crusher, which is coupled to a conveyor system IPCC systems could lead to the

Towards development Erdenet Mining Corporation

In the world mining practice, inpit crushing and conveying technology (ICCT) is introduced at the time of the depth of the career exceeds 150 m The depth of our Openpit mine has reached 195 m, and the final depth of the 905 meter bottom project is 495 meters Transportation costs continue to rise in the current context of increasing the

Contribution to the capacity determination of semimobile inpit

2016年7月22日 ABSTRACT InPit Crushing and Conveying (IPCC) has gained momentum in recent years to replace trucks partially or fully in large open pit mines because of the shoveltruck system's increasing fuel and Expand 1 Highly Influenced 5 Excerpts; Save

v117n6a11 Inpit crusher location as a dynamic location

2018年12月11日 Inpit crushingconveying (IPCC) systems have been known in the mining industry for many decades The idea was introduced in 1956 in Germany Today, the cost efficiency and high reliability of IPCC make it more appealing than conventional shoveltruck operation, especially in longer life projects with lengthy transportation distances and high

(PDF) OpenPit Mine Production Scheduling and Crusher

2021年5月4日 InPit Crushing and Conveying Systems with the HighAngle Conveyor Mining 2021; 1(1):5979 Dingbang Liu has been responsible for model development, computer programming, writing

Inpit crushing and conveying technology in openpit mining

2020年7月2日 ABSTRACT InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the future Today, it has become more necessary than ever to reduce the cost of truck haulage, which accounts for roughly half the operating costs of mining

Determination of semimobile inpit crushing and conveying

2021年2月12日 Inpit crushing and conveying (IPCC) is a material handling system with a feed system, crusher, conveyors and discharge systems as shown in Fig 1 It involves inpit crushing of materials The use of IPCC is justified by its benefits such as reduced operational costs due to minimal trucks usage, high production output and reduced gas

New focus on inpit crushing systems (Journal Article)

2008年6月15日 With diesel fuel prices skyrocketing, producers are taking a close look at this alternative (inpit semimobile crushing/conveying systems) to conventional haulage and crushing 6 figs Authors: Casteel, K Publication Date: Sun Jun 15 00:00:00 EDT 2008 OSTI Identifier: Resource Type:

Crushing Energy Efficiency North American Mining Magazine

2021年6月10日 Another option to help improve comminution efficiency is inpit crushing and conveying The advantage here is found in the transportation of ore between mine face and crusher “Conveyors are more energy efficient that trucks,” explained Metso Outotec’s LynchWatson and Alan Boylston, director, process engineering development, sales 10